Rhenium Plate Price & List

| Spec. |

Thickness (mm) |

Width (mm) |

Length (mm) |

| Re-PT005 |

5 |

≤350 |

≥50 |

| Re-PT010 |

10 |

≤350 |

≥50 |

| Re-PT015 |

15 |

≤350 |

≥50 |

| Re-PT020 |

20 |

≤350 |

≥50 |

| Re-PT025 |

25 |

≤350 |

≥50 |

| Customizable |

Customizable |

Customizable |

Customizable |

Note: We provide customized service. If you don't find the plates you want, please send us an email directly. We can customize it according to your requirements.

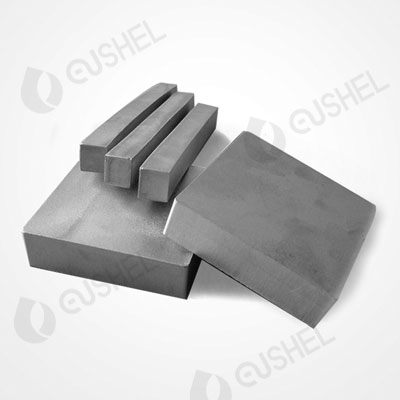

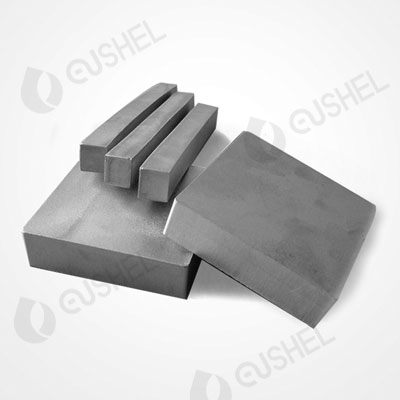

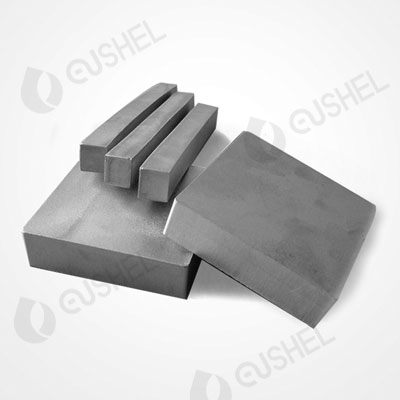

Rhenium plate is a type of rhenium metal plate with a thickness more than 5 mm. It is made by pressing high-purity rhenium powder, sintering it into rhenium slab, and then rolling, annealing, and other processes to produce high-purity rhenium plate.

Production Process of Rhenium Plate

Step 1: Pulverizing and reduction:

First, the high-purity ammonium rhenate crystal particles are pretreated and broken to - 100-300 mesh; then, the low-temperature reduction is carried out in hydrogen, and the reduction temperature is controlled at 230-350 ℃, and the reduction products are reprocessed and ground to pass the - 100-150 mesh sieve; then, the secondary reduction is carried out in hydrogen, and the reduction temperature is controlled at 800-950 The pure rhenium powder with oxygen content less than 0.1%, particle size 2-6 μ m and purity more than 99.95% was obtained;

Step 2: Press forming:

Adopt detachable mould to press, make the compact separate from the die and transfer safely without any force; at the same time, add 1.5-3% (mass percentage) lubricant into the powder to make compact with thickness of 5-15 mm and boson ratio of more than 16;

Step 3: Sintering deformation:

After dewaxing and pre sintering, the compacts are sintered at high temperature under the protection of hydrogen. The sintering temperature is controlled at 2000-2340 ℃ until the density reaches more than 95% of the theoretical density and the thickness is 4-12 mm. The compacts are uniformly and finely crystallized;

Step: Rolling deformation:

Cold rolling at room temperature and strict control of 8-15% pass deformation are adopted; high temperature annealing treatment is carried out in hydrogen after each pass deformation with annealing temperature of 1500-1800 ℃ and annealing time of 30-120 Min, to eliminate the work hardening and control the crystallization to be uniform and fine, and then to carry out the next rolling, so as to cycle the processing and heat treatment until reaching the required size; finally, to obtain the finished rhenium sheet after annealing treatment.

Rhenium Plate Application

Rhenium plates can be used in various occasions and fields depending on their purity, thickness, and shape. The details are as follows:

1. Rhenium plates can be processed into components, structural components, resistance components, and connectors for high-tech equipment;

2. Rhenium plates can be used for processing key structural components of high-performance fighter jets and large aircraft engines, as well as ultra-high temperature alloy components in the fields of aerospace and military weapon equipment manufacturing;

3. Rhenium plates can be processed into rhenium products such as

rhenium bars,

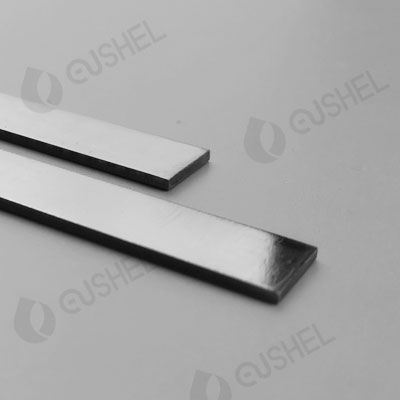

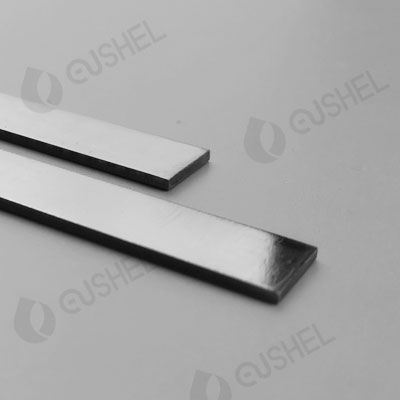

rhenium sheets,

rhenium strips,

rhenium crucibles, etc;

4. High purity rhenium plates can be processed into

rhenium sputtering targets for sputtering coating.

| Spec. |

Thickness (mm) |

Width (mm) |

Length (mm) |

| Re-PT005 |

5 |

≤350 |

≥50 |

| Re-PT010 |

10 |

≤350 |

≥50 |

| Re-PT015 |

15 |

≤350 |

≥50 |

| Re-PT020 |

20 |

≤350 |

≥50 |

| Re-PT025 |

25 |

≤350 |

≥50 |

| Customizable |

Customizable |

Customizable |

Customizable |

Related Products

Plate Series

Chromium plate is made from high-purity chromium powder, which is melted or pressed and sintered to form a chromium plate blank, and then processed into a chromium plate that meets the required size.

https://www.fushel.com/plate/chromium-plate.html

Hafnium plate is a type of high-purity hafnium plate made by melting or pressing and sintering high-purity hafnium powder into hafnium slab, followed by a series of processes such as rolling, annealing, and surface treatment.

https://www.fushel.com/plate/hafnium-plate.html

Molybdenum plate is made by pressing high-purity molybdenum powder, sintering it into molybdenum slab, and then rolling, annealing, and other processes to produce high-purity molybdenum plate.

https://www.fushel.com/plate/molybdenum-plate.html

Niobium plate is made by pressing high-purity niobium powder, sintering it into niobium slab, and then rolling, annealing, and other processes to produce high-purity niobium plate.

https://www.fushel.com/plate/niobium-plate.html

Tantalum plate is made by pressing high-purity tantalum powder, sintering it into tantalum slab, and then rolling, annealing, and other processes to produce high-purity tantalum plate.

https://www.fushel.com/plate/tantalum-plate.html

Titanium plate is a high-purity titanium plate made by melting or pressing and sintering high-purity titanium powder to form titanium slab, and then undergoing a series of processes such as rolling, annealing, and surface treatment.

https://www.fushel.com/plate/titanium-plate.html

Vanadium plate is made from high-purity vanadium powder, which is melted or pressed and sintered to form a vanadium plate blank, and then processed into a vanadium plate that meets the required size.

https://www.fushel.com/plate/vanadium-plate.html

Tungsten plate refers to tungsten metal plate with thickness more than 5 mm. The surface of tungsten plate can have rolling surface, alkali washing surface and polished surface.

https://www.fushel.com/plate/tungsten-plate.html

Zirconium plate is a high-purity zirconium plate made by melting or pressing and sintering high-purity zirconium powder to form zirconium slab, and then undergoing a series of processes such as rolling, annealing, and surface treatment.

https://www.fushel.com/plate/zirconium-plate.html