440C Stainless Steel Powder (S44004 / SUS440C / X105CrMo17 1.4125)

Available440C Stainless Steel Powder for SaleWholesale & RetailManufacturer & SupplierFactory Supply

Symbol: 440CPurity: ASTM S44004, JIS SUS440C, EN X105CrMo17 1.4125Particle size: 0.01 - 250 umShape: Spherical, irregular, etc.Min. Order: 1 kgIn stock: AvailableShips to: Worldwide

440C Stainless Steel Powder Price & List

| Product Name |

Composition |

Shape |

Available |

| 440C Stainless Steel Powder |

Cr 16-18%, C 0.95-1.2%, Mo 0.4-0.8%, Si<1%, Mn <1%, Fe balance |

Spherical |

D50 10-14 um |

| 440C Stainless Steel Powder |

Cr 16-18%, C 0.95-1.2%, Mo 0.4-0.8%, Si<1%, Mn <1%, Fe balance |

Spherical |

10-45 um |

| 440C Stainless Steel Powder |

Cr 16-18%, C 0.95-1.2%, Mo 0.4-0.8%, Si<1%, Mn <1%, Fe balance |

Spherical |

15-53 um |

| 440C Stainless Steel Powder |

Cr 16-18%, C 0.95-1.2%, Mo 0.4-0.8%, Si<1%, Mn <1%, Fe balance |

Spherical |

45-105 um |

| 440C Stainless Steel Powder |

Cr 16-18%, C 0.95-1.2%, Mo 0.4-0.8%, Si<1%, Mn <1%, Fe balance |

Spherical |

45-150 um |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

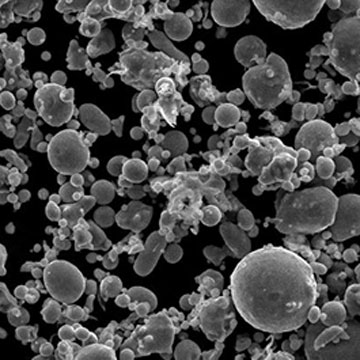

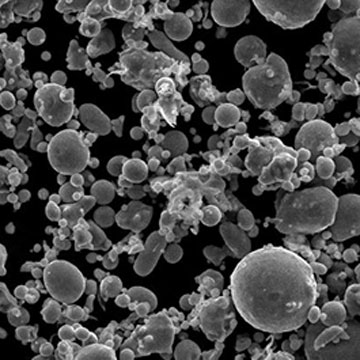

440C stainless steel powder is a martensitic stainless steel powder with carbon content of 0.95-1.2% and chromium content of 16-18%. 440C stainless steel powder has strong rust resistance and is a high-quality stainless steel alloy powder. Internationally, the composition of 440C stainless steel powder is basically the same. But the standard is different. The main standards are: ASTM S44004 440C, JIS SUS440C, ISO X105CrMo17, EN X105CrMo17 1.4125, GB 108Cr17.

440C Stainless Steel Powder Application

The 440C stainless steel powder produced by FUSHEL features low oxygen content, regular shape, high tap density, stable particle size distribution and chemical composition control, and can be used in the following occasions:

1. Used for 3D printing (additive manufacturing), thermal spraying, metal injection molding and other occasions;

2. Mainly used to manufacture bearing parts working in corrosive environment and non lubricated strong oxidation atmosphere;

3. Used as corrosion resistant high temperature bearing steel;

4. Used to make high-quality knives, such as medical scalpels, scissors, nozzles, bearings, etc.