Chromium Carbide Powder (Cr3C2)

AvailableChromium Carbide Powder for SaleWholesale & RetailManufacturer & SupplierFactory Supply

Symbol: Cr3C2Purity: 99% - 99.9%Particle size: 0.01 - 250 umShape: Irregular, spherical, etc.Min. Order: 1 kgIn stock: AvailableShips to: Worldwide

Chromium Carbide Powder Price & List

| Product Name |

Purity |

Spec. |

O |

N |

C-free |

C-total |

| Chromium Carbide Powder |

≥99% |

D50 0.5-1 um |

≤0.8 % |

≤0.05 % |

≤0.1 % |

12.8-13.4% |

| Chromium Carbide Powder |

≥99.5% |

D50 1-3 um |

≤0.5 % |

≤0.05 % |

≤0.1 % |

12.8-13.4% |

| Chromium Carbide Powder |

≥99.9% |

-100, +325 mesh |

≤0.3 % |

≤0.05 % |

≤0.1 % |

12.8-13.4% |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

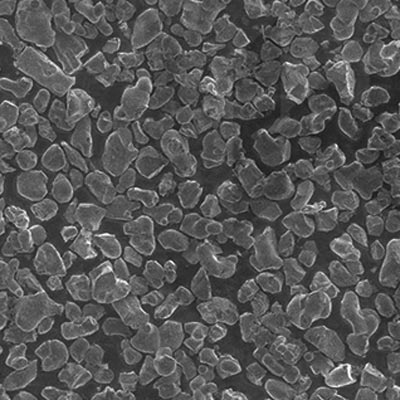

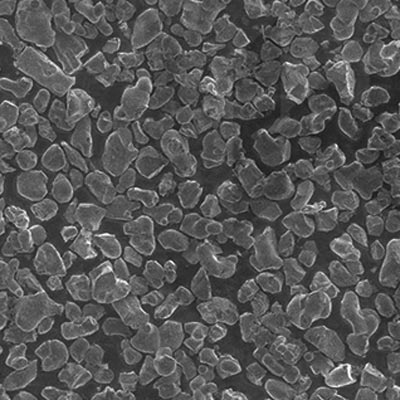

Chromium carbide is a kind of carbide ceramic powder with gray appearance and metallic luster. The chemical formula is Cr3C2. The density is 6.68 g/cm3; The melting point is 1890 ℃, and the boiling point is 3800 ℃. Chromium carbide has good wear resistance, corrosion resistance and oxidation resistance under high temperature environment (1000~1100 ℃). It belongs to a metal ceramic.

According to different particle sizes, chromium carbide powder can be divided into coarse chromium carbide powder, fine chromium carbide powder, extremely fine chromium carbide powder, ultra-fine chromium carbide powder and chromium carbide nanopowder. At present, we mainly provide superfine chromium carbide powder.

Chromium Carbide Powder Application

Chromium carbide powder has good wear resistance, corrosion resistance and oxidation resistance under high temperature environment (1000~1100 ℃). It can be used in the following situations:

1. The cemented carbide particles made of chromium carbide powder and nickel chromium alloy can be used as high-temperature, wear-resistant, oxidation resistant and acid resistant coatings by plasma spraying, and are widely used in aircraft engines and petrochemical machinery components, which can greatly improve the service life of machinery. It is also commonly used as grain refiner of cemented carbide and other wear-resistant and corrosion-resistant components. Cermet based on Cr3C2 has excellent oxidation resistance at high temperature.

2. Used for chromium carbide ceramics. As a melt blown material, coarse chromium carbide powder forms a melt blown coating on the surface of metals and ceramics, which endows the latter with wear resistance, heat resistance, corrosion resistance and other properties. It is widely used in aircraft engines and petrochemical mechanical devices to greatly improve the mechanical life. It is also used for spraying semiconductor films.