Silicon Nitride Powder Price & List

| Product Name |

Purity |

Shape |

Spec. |

N |

O |

C |

Impurity |

Si-free |

| Silicon Nitride Powder |

≥99.99% |

β-phase, >60% |

D50 2.2-3.2 um |

> 38% |

< 1% |

< 0.2% |

< 20 ppm |

< 0.5% |

| Silicon Nitride Powder |

≥99.98% |

α-phase, >70% |

D50 1.8-3.0 um |

> 38% |

< 1% |

< 0.3% |

< 150 ppm |

< 0.5% |

| Silicon Nitride Powder |

≥99.95% |

α-phase, >75% |

D50 < 0.8 um |

> 38% |

/ |

< 0.3% |

< 500 ppm |

/ |

| Silicon Nitride Powder |

≥99.97% |

α-phase, >75% |

D50 < 3.2 um |

> 38.5% |

< 1.2% |

< 0.3% |

< 300 ppm |

< 0.5% |

| Silicon Nitride Powder |

≥99.60% |

α-phase, >91% |

D50 < 0.8 um |

> 38% |

< 2.5% |

< 0.3% |

< 0.4% |

/ |

| Silicon Nitride Powder |

≥99.65% |

α-phase, >91% |

D50 < 2.8 um |

> 38.5% |

< 1.5% |

< 0.3% |

< 0.35% |

< 0.6% |

| Silicon Nitride Powder |

≥97% |

β-phase, >75% |

D97 < 45 um |

> 36.5% |

< 2.0% |

< 0.5% |

< 3% |

< 2% |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

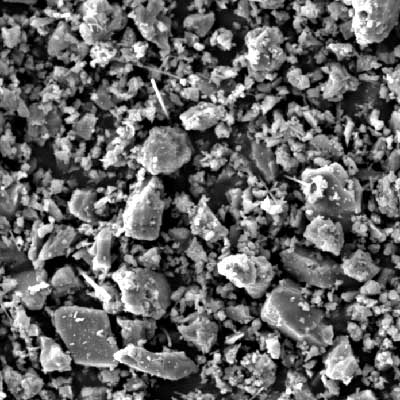

Silicon nitride powder is a kind of nitride ceramic powder with gray, white or offwhite appearance. The chemical formula is Si3N4. Silicon nitride powder is an important structural ceramic material with high hardness, lubricity, wear resistance and oxidation resistance at high temperature. Moreover, it can also resist cold and hot shocks. When heated to more than 1000 ℃ in the air, it will not be broken after sharp cooling and heating. It is precisely because silicon nitride ceramics have such excellent characteristics that people often use it to manufacture mechanical components such as bearings, turbine blades, mechanical seal rings, permanent molds, etc.

Silicon Nitride Powder Application

Silicon nitride has the characteristics of high strength and high temperature resistance. Among ceramic materials, it has the best comprehensive mechanical properties, heat shock resistance, oxidation resistance, wear resistance and corrosion resistance. It is the first candidate material for ceramics used in thermal engine parts. According to the different purity and particle size, silicon nitride powder can be used in different occasions and fields. The details are as follows:

1. In the mechanical industry, silicon nitride powder can be used as silicon nitride ceramic bearing ball, roller, ball race, tooling, new ceramic tools, pump plunger, spindle sealing materials, etc.

2. In the chemical industry, silicon nitride powder is used as wear-resistant and anti-corrosion parts of silicon nitride ceramics. Such as silicon nitride ball valve, pump body, combustion vaporizer, filter, etc.

3. In the metallurgy industry, silicon nitride ceramics are self lubricating due to their high temperature resistance, low friction coefficient. It is stable for most metal and alloy solutions. Therefore, silicon nitride powder can be used to make tools and dies for metal material processing, such as silicon nitride core rod, extrusion, wire drawing die, roll, transfer roll, heating element clamp, thermocouple sleeve, metal heat treatment support, crucible, aluminum liquid guide, aluminum ladle lining, etc.