Silicon Carbide Nanopowder Price & List

| Product Name |

Purity |

Shape |

Available |

| Silicon Carbide Nanopowder |

98% - 99.9% |

Hexagonal |

30 nm, 50 nm, 100 nm |

Note: We provide customized service. If you don't find the powder you want, please send us an email directly. We can customize it according to your requirements.

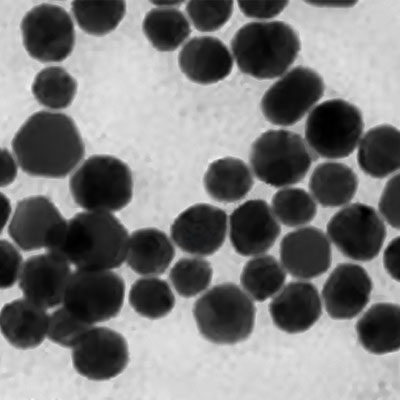

Silicon carbide nanopowder refers to silicon carbide nanoparticles with particle size less than 100 nm. The particle size of silicon carbide nanopowder is mainly determined by measurement under scanning electron microscope (SEM).

Nano silicon carbide powder should be sealed and stored in a dry and cool environment. It should not be exposed to the air for a long time to prevent moisture and agglomeration, which will affect the dispersion performance and use effect. In addition, it should avoid heavy pressure and contact with oxidants.

Silicon Carbide Nanopowder Application

Nano silicon carbide powder can be used in many occasions. The details are as follows:

1. Nano-SiC powder has good compatibility in polymer composites, good dispersion, and good basic adhesion. After modification, the tensile strength of high-strength nylon alloy is more than 150% higher than that of ordinary PA6, and the wear resistance is more than 3 times higher. It is mainly used for polymer parts of armored tracked vehicles, automobile steering parts, textile machinery, mining machinery liner, train parts, etc., which can be densified by sintering at a lower temperature;

2. Wear resistance of modified special engineering plastic polyether ether ketone (PEEK): adding about 5% nano silicon carbide powder can greatly improve the wear resistance of PEEK (more than 30% of the original);

3. Application of nano silicon carbide in rubber tires: adding about 2% of nano silicon carbide powder can improve the wear resistance by 20% - 40% without changing the formula of the original rubber;

4. Nano-SiC composite coating on metal surface: using the second mixed particle of nano particles and nickel as the base metal, an electrodeposited composite coating with high density and excellent adhesion is formed on the metal surface. Its metal surface has the characteristics of superhard (wear-resistant), antifriction (self-lubricating) and high temperature resistance. The microhardness of the composite coating is greatly improved, the wear resistance is increased by 2-3 times, the service life is increased by 3-5 times, the adhesion between the coating and the substrate is increased by 40%, the covering ability is strong, and the coating is uniform, smooth and fine;

5. It is used for high-performance structural ceramics (such as rocket nozzles, nuclear industry, etc.), wave absorbing materials, anti-wear lubricating grease, high-performance brake pads, high hardness wear-resistant powder coatings, composite ceramics reinforcement and toughening, etc;

6. Structural coatings, functional coatings, protective coatings, wave absorbing materials, stealth materials, etc. used in the aerospace industry;

7. Protective armor for tanks and armored vehicles;

8. It can be used as ceramic tools, cutting tools, measuring tools and molds;

9. Structural ceramics, functional ceramics and engineering ceramics that can be used for special purposes; Igniter; Electric heating element for electrical industry, far infrared generator.