Tantalum Bar List

| Spec. |

Purity |

Shape |

Section Size (mm) |

Length (mm) |

| Ta-BS015 |

≥99.95% |

Square |

15 x 15 |

≤600 |

| Ta-BS020 |

≥99.95% |

Square |

20 x 20 |

≤1000 |

| Ta-BS045 |

≥99.95% |

Square |

45 x 45 |

≤1200 |

| Ta-BS060 |

≥99.95% |

Square |

60 x 60 |

≤1500 |

| Ta-BF015030 |

≥99.95% |

Rectangle |

15 x 30 |

≤600 |

| Ta-BF020040 |

≥99.95% |

Rectangle |

20 x 40 |

≤1000 |

| Ta-BF030060 |

≥99.95% |

Rectangle |

30 x 60 |

≤1200 |

| Ta-BR002 |

≥99.95% |

Round |

φ2 |

≤3000 |

| Ta-BR005 |

≥99.95% |

Round |

φ5 |

≤3000 |

| Ta-BR010 |

≥99.95% |

Round |

φ10 |

≤3000 |

| Ta-BR020 |

≥99.95% |

Round |

φ20 |

≤1600 |

| Ta-BR050 |

≥99.95% |

Round |

φ50 |

≤1400 |

| Customizable |

Customizable |

Customizable |

Customizable |

Customizable |

Note: We provide customized service. If you don't find the bars you want, please send us an email directly. We can customize it according to your requirements.

Tantalum bar refers to a type of tantalum metal bar made by melting or sintering high-purity tantalum powder and then undergoing a series of process treatments. According to the different cross-section shapes, tantalum bars can be divided into tantalum round bars, tantalum flat bars, tantalum square bars, hexagonal tantalum bars and so on. Polished tantalum rod is a kind of tantalum rod with polished surface. Tantalum bars can be customized according to customers' requirements, and can also undergo surface treatments such as polishing, sandblasting, electrochemical polishing, etc.

Tantalum Bar Processing

Material preparation: Select appropriate tantalum bar materials and cut them into appropriate lengths according to engineering requirements.

Rough machining: Preliminary machining of tantalum bars by drilling, turning, milling, and other methods to bring them closer to the target shape and size.

Heat treatment: Tantalum has good ductility and plasticity, and its mechanical properties can be improved through heating treatment. Usually, a vacuum heat treatment furnace is used for treatment.

Precision machining: precision lathes, grinders, and other tools are used to perform precision machining on tantalum rods to achieve precise shapes and dimensions.

Cleaning: Clean the oil and impurities on the surface of tantalum bars, usually using a solvent or ultrasonic cleaning machine.

Testing: Quality testing of processed tantalum bars is carried out through non-destructive and destructive testing methods, such as X-ray testing, ultrasonic testing, tensile testing, etc.

Packaging: Packaging and labeling of qualified tantalum bars to ensure their quality and traceability.

Tantalum Bar Application

Tantalum bars can be adjusted and optimized according to specific engineering requirements and factors such as material, shape, and size of the rods. It is mainly used in the following occasions and fields:

High temperature alloy: Tantalum bars have good high-temperature stability and corrosion resistance, and can be used for manufacturing high-temperature alloy materials, such as aerospace, aviation engines, rocket engines, etc.

Medical devices: Tantalum has good biocompatibility and mechanical properties, and can be used to manufacture medical devices, such as artificial heart valves, artificial bones, implants, etc.

Chemical equipment: Tantalum bars can be used to manufacture chemical equipment, such as tower reactors, reactors, evaporators, etc. They have good corrosion resistance in corrosive environments such as strong acids and alkalis.

Electronic devices: Tantalum bars can be used to manufacture electronic devices such as capacitors, resistors, etc. Due to their good conductivity and corrosion resistance, tantalum can improve the performance and stability of devices.

Nuclear power industry: Tantalum bars can be used to manufacture parts in nuclear reactors, such as fuel rods, parts inside reactors, etc. Because of its good radiation resistance and high temperature stability, tantalum can ensure the normal operation of reactors.

Tantalum Round Bar

Tantalum round bar refers to a type of tantalum metal rod with a circular cross-sectional shape, and is also the most common type of tantalum bar.

| Spec. |

Purity |

Shape |

Section Size (mm) |

Length (mm) |

| Ta-BR002 |

≥99.95% |

Round |

φ2 |

≤3000 |

| Ta-BR005 |

≥99.95% |

Round |

φ5 |

≤3000 |

| Ta-BR010 |

≥99.95% |

Round |

φ10 |

≤3000 |

| Ta-BR020 |

≥99.95% |

Round |

φ20 |

≤1600 |

| Ta-BR050 |

≥99.95% |

Round |

φ50 |

≤1400 |

| Customizable |

Customizable |

Customizable |

Customizable |

Customizable |

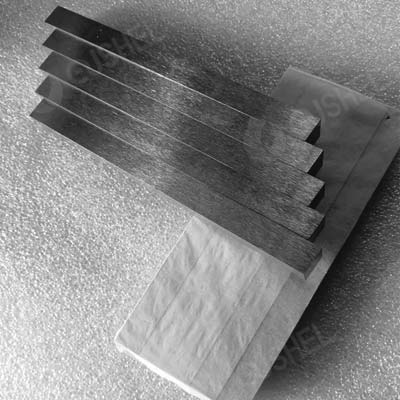

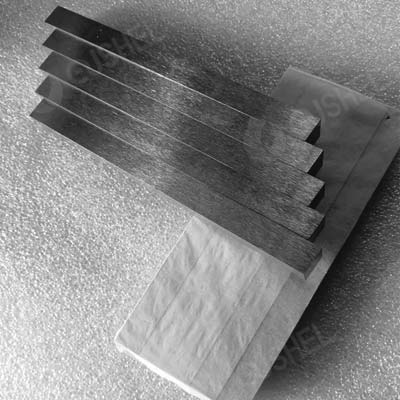

Tantalum Flat Bar

Tantalum flat bar refers to a type of tantalum metal bar with a rectangular cross-sectional shape. It needs to be produced through special rectangular molds.

| Spec. |

Purity |

Shape |

Section Size (mm) |

Length (mm) |

| Ta-BF015030 |

≥99.95% |

Rectangle |

15 x 30 |

≤600 |

| Ta-BF020040 |

≥99.95% |

Rectangle |

20 x 40 |

≤1000 |

| Ta-BF030060 |

≥99.95% |

Rectangle |

30 x 60 |

≤1200 |

| Customizable |

Customizable |

Customizable |

Customizable |

Customizable |

Tantalum Square Bar

Tantalum square bar refers to a type of tantalum metal bar with a square cross-sectional shape. It needs to be produced through special square molds.

| Spec. |

Purity |

Shape |

Section Size (mm) |

Length (mm) |

| Ta-BS015 |

≥99.95% |

Square |

15 x 15 |

≤600 |

| Ta-BS020 |

≥99.95% |

Square |

20 x 20 |

≤1000 |

| Ta-BS045 |

≥99.95% |

Square |

45 x 45 |

≤1200 |

| Ta-BS060 |

≥99.95% |

Square |

60 x 60 |

≤1500 |

| Customizable |

Customizable |

Customizable |

Customizable |

Customizable |

Related Products

Bar Series

Chromium bar is a high-precision chromium metal bar made by smelting or sintering high-purity chromium powder into chromium billet, and then undergoing a series of processes such as forging, rolling, machining, polishing, etc.

https://www.fushel.com/bar/chromium-bar.html

Hafnium bar is a high-purity metal hafnium bar made by melting or sintering high-purity hafnium powder into hafnium billets, and then undergoing a series of processes such as machining and polishing.

https://www.fushel.com/bar/hafnium-bar.html

Molybdenum bar refers to a type of high-purity molybdenum bar made by sintering or melting high-purity molybdenum powder into a molybdenum bar blank, which is then forged, rolled, machined, polished, and other processes.

https://www.fushel.com/bar/molybdenum-bar.html

Niobium bar refers to a type of high-purity niobium metal bar made by melting or pressing and sintering high-purity niobium powder into niobium billets, and then undergoing a series of processes such as extrusion, forging, rolling, and stretching.

https://www.fushel.com/bar/niobium-bar.html

Rhenium bar is a high purity rhenium metal bar made by smelting or static pressing high purity rhenium powder into rhenium billets, and then undergoing a series of processes such as forging, rolling, and annealing.

https://www.fushel.com/bar/rhenium-bar.html

Titanium bar refers to a type of high-purity titanium bar made by pressing and forming high-purity titanium powder, followed by a series of processes such as sintering, extrusion, processing, and polishing.

https://www.fushel.com/bar/titanium-bar.html

Vanadium bar refers to a high-purity vanadium metal bar made by smelting or pressing and sintering high-purity vanadium powder into vanadium billets, and then rolling, machining, and other processes.

https://www.fushel.com/bar/vanadium-bar.html

Tungsten bar refers to a high-precision tungsten bar made by melting or sintering high-purity tungsten powder into a tungsten slab or bar blank, followed by a series of processes such as forging, rolling, machining, polishing, etc.

https://www.fushel.com/bar/tungsten-bar.html

Zirconium bar refers to a type of zirconium metal bar that uses high-purity zirconium powder to be melted or pressed and sintered into zirconium billets, and then machined into different shapes.

https://www.fushel.com/bar/zirconium-bar.html