Aluminum Tube Target List

| Product Name |

Purity |

Size (inch) |

Thickness (mm) |

| Aluminum Tube Target |

99.99% - 99.9995% |

0 - 48 |

≥ 1 |

Note: We provide customized service. If you don't find the sputtering targets you want, please send us an email directly. We can customize it according to your requirements.

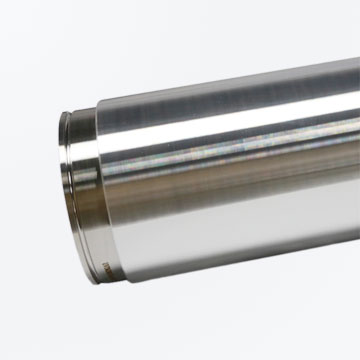

Aluminum Tube Targets are the core form and industrial standard for rotary sputtering targets. They specifically refer to hollow cylindrical aluminum or aluminum alloy target assemblies used in rotary sputtering systems. It is an integrated functional unit, typically made by permanently bonding an aluminum (or aluminum alloy) target tube to an inner metal backing tube through high-temperature welding.

Core Working Features:

In sputtering equipment, the

aluminum tube target is mounted on a rotating drive shaft and spins at high, uniform speeds around its central axis in a vacuum chamber. Plasma forms a ring-shaped etching area on its outer cylindrical surface, and the continuous rotation of the target ensures uniform sputtering over the entire circumference.

Core Value and Strategic Position:Foundation of Industrial Production Efficiency: With a high material utilization rate (70%-85%) and stable high-power operation capability, aluminum tube targets are the only viable choice for large-scale, continuous coating production lines (such as those in flat-panel displays and coated glass), making cost-effective production feasible. Without aluminum tube targets, the cost of modern large-area coating industries would be prohibitive.

Guarantee of Uniformity and Stability: The uniform etching produced by rotation, combined with precision magnetic field design, ensures unparalleled film thickness uniformity across large-area substrates (up to several meters wide) and a consistent deposition rate throughout the entire lifespan of the target.

Reflection of System Integration: An aluminum tube target is not merely a material component but a high-end electromechanical assembly integrating high-purity materials, precision manufacturing, dissimilar metal welding, thermodynamic design, and mechanical drive interfaces. Its performance directly determines the capacity, yield, and operational costs of the entire PVD production line.

Aluminum Tube Target Application

The applications of aluminum tube targets revolve around the core needs of "large-area" and "continuous production", making them essential consumables in the following industries:

1. Flat Panel Display Industry – Dominant Application Market:Application Details: In the TFT-LCD and OLED array processes, aluminum tube targets are used to deposit all metal layers, including gate lines, data lines, source/drain electrodes, and capacitive electrodes. A single G10.5 generation LCD production line may require hundreds of aluminum tube targets.

Process Scenario: Glass substrates, after pre-treatment, continuously pass through a multi-meter long PVD chamber at a constant speed. Several aluminum tube targets are arranged in parallel inside the chamber (sometimes in combination with other materials) and sputter coating occurs simultaneously under a precisely controlled magnetic field and process gas environment.

Technical Requirements:

Extreme Uniformity: The sputtering rate deviation at any position on the target tube must be less than ±3%.

Long Lifespan and Stability: A single target must operate continuously and stably for thousands of hours, with film sheet resistance fluctuations controlled within a very narrow range.

Ultra-low Particle Contamination: Ensuring that macro defects generated on the large glass substrate are limited to single-digit numbers.

2. Large-Area Functional Coatings:Architectural and Automotive Low-E Glass:

Role: Aluminum films serve as infrared reflective or blocking layers in multi-layer film systems, which are key to achieving energy-saving and insulation functions.

Production Mode: In an "online" or "offline" process, functional coatings are continuously deposited on float glass substrates, which are several meters wide, using a multi-chamber system. The high efficiency and stability of aluminum tube targets are the cornerstone of this process's commercial success.

Flexible Roll-to-Roll Coatings:

Applications: Includes high-barrier packaging films (food, pharmaceuticals), metallized capacitor films, and decorative/label materials.

Process Characteristics: Using a "Roll-to-Roll" method, plastic film substrates pass through the vacuum chamber at high speeds (hundreds of meters per minute) for aluminum coating. Aluminum tube targets must withstand extremely high deposition rates and near-continuous production rhythms.

3. Thin-Film Solar Cells:Application Details: In silicon-based thin-film or copper indium gallium selenide (CIGS) solar cells, aluminum tube targets are used to create back-contact electrodes or interconnect conductive pathways within the module.

Technical Requirements: Along with ensuring conductivity, the focus is on the adhesion between the film and the underlying materials, as well as long-term environmental stability. Given the extreme cost sensitivity in the photovoltaic industry, the high utilization properties of aluminum tube targets are especially important.

4. Advanced Semiconductor Packaging (Emerging Applications):Future Prospects: As panel-level packaging technology develops, there is a need to deposit re-routing layers (RDL) on square substrates (with side lengths exceeding 500mm). Traditional multi-planar target solutions are inefficient, making the use of large-area aluminum tube targets for single-scan coating a highly promising, efficient solution.

Technical Requirements: Must meet semiconductor-level purity and cleanliness requirements, with fine patterning capability being key for the thin film.